Unknown Facts About Premier Aluminum Llc

Unknown Facts About Premier Aluminum Llc

Blog Article

The smart Trick of Premier Aluminum Llc That Nobody is Talking About

Table of ContentsThe Main Principles Of Premier Aluminum Llc Indicators on Premier Aluminum Llc You Need To KnowExamine This Report about Premier Aluminum LlcPremier Aluminum Llc for Dummies

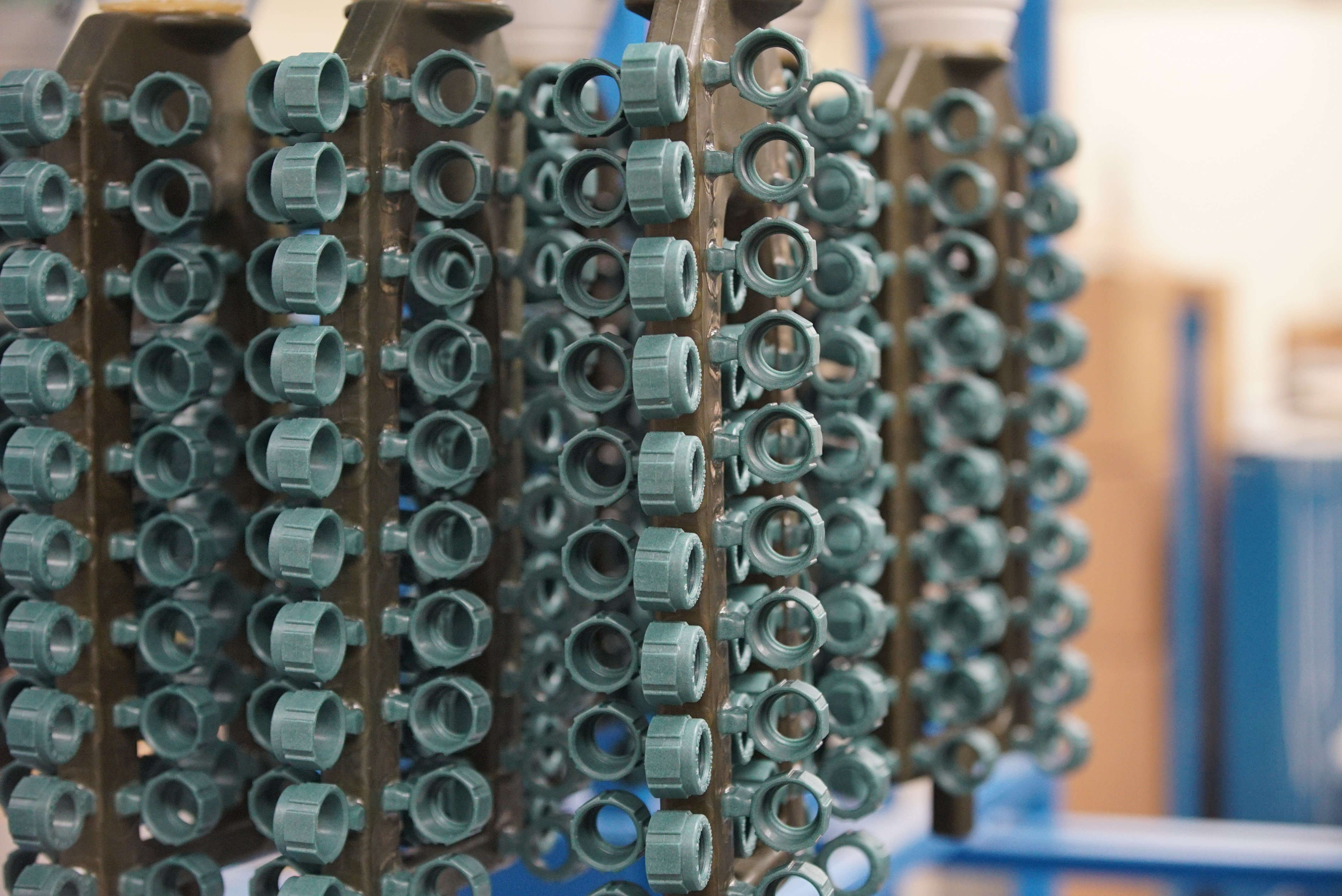

(https://premieraluminum.edublogs.org/2024/12/12/top-rated-aluminum-casting-company-why-premier-aluminum-llc-stands-out/)Making use of low price and unqualified vendors can cause quality concerns, and lost time and money in the long run. To aid you with the process, below are some points to think about when selecting the ideal metal spreading distributor.

A business that only uses the investment spreading procedure will certainly try to sell you on why that procedure is best for your application (Foundry near me). Yet what happens if using the sand casting process is best for you and your requirements? Instead, seek a vendor that offers an array of casting procedures so the very best alternative for YOU is picked

If dealing with a single resource for every one of your spreading needs is essential to you, the distributor needs to be varied in its capabilities. When integrated with various other integrated capacities, this can aid streamline and compress the supply base. When selecting the best casting supplier, cautious consideration needs to be provided to high quality, solution, and price.

Top Guidelines Of Premier Aluminum Llc

Customers progressively choose casting distributors that have machining capabilities. If the spreading vendor uncovers a problem throughout machining, the problem is fixed much faster with no conflict over whose mistake it is.

Trouble or no, integrated machining simplifies the supply chain and reduces dealing with time and delivery price prior to the item makes it to the customer. What do you require from your casting vendor? Are you trying to find a person to simply provide a steel component to your doorstep or do you need much more? If you do not have in-house metallurgy expertise, validate that the supplier can give advice in selecting the proper alloy based on your specific application.

Others will surpass the letter of the PO to aid you conserve money and time. Do you have demands for both ferrous and non-ferrous alloys? Some foundries are restricted or specialized. Make certain the supplier can fulfill all your material or alloy needs to get rid of the need for multiple suppliers.

Little Known Facts About Premier Aluminum Llc.

Research the supplier's internet site. Talk to a sales rep or organization associate.

Aluminum is likewise lightweight and has good corrosion resistance, making it optimal for applications where weight and longevity are essential factors. Additionally, aluminum spreading is an economical technique of manufacturing, as it calls for less energy and sources than other techniques. Iron casting, on the various other hand, entails pouring molten iron right into a mold to produce a desired shape.

The 4-Minute Rule for Premier Aluminum Llc

Iron casting is likewise able to hold up against heats, making it suitable for use in applications such as engine components and industrial equipment. However, iron casting can be more expensive than aluminum casting as a result of the greater expense of resources and the energy article required to thaw the iron. When determining in between light weight aluminum casting and iron casting, it is important to consider the specific requirements of the application.

In verdict, both light weight aluminum casting and iron casting have their very own distinct advantages and negative aspects. There are 3 sub-processes that drop under the category of die spreading: gravity die casting (or irreversible mold casting), low-pressure die spreading and high-pressure die casting. To get to the ended up product, there are 3 main alloys used as die casting product to choose from: zinc, aluminum and magnesium. Report this page